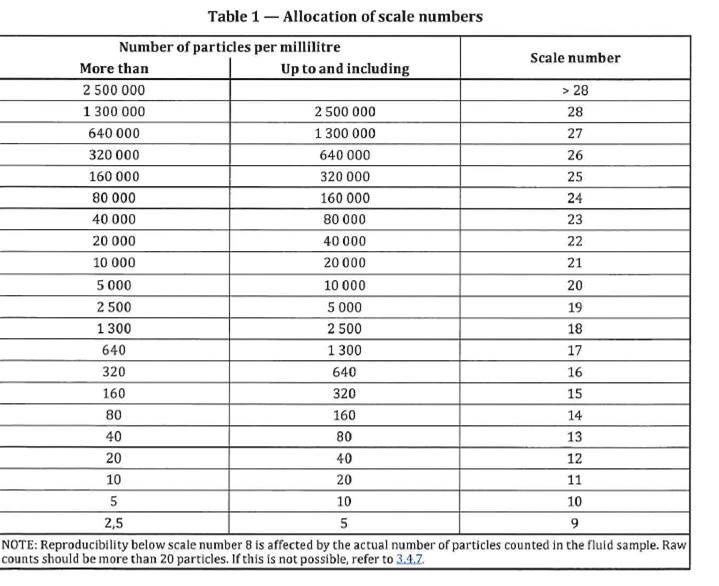

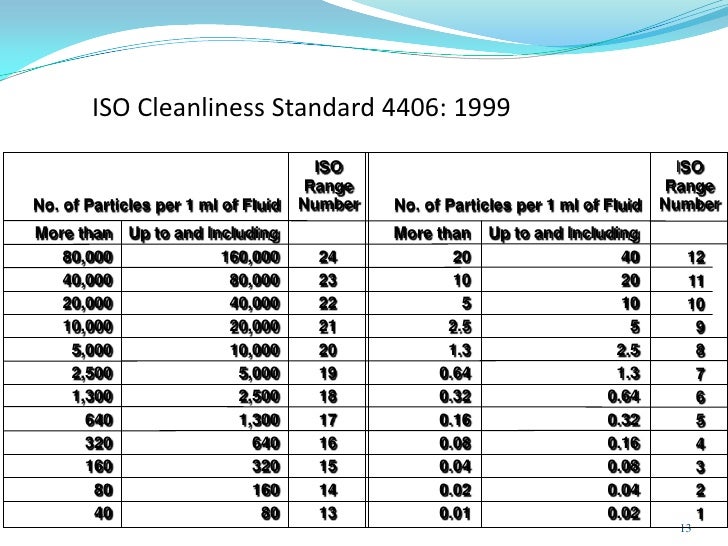

Then the pressure drop increases dramatically. Clogging As a safety screen accumulates particles, the pressure drop will slowly increase until the screen is almost fully clogged. This lists fluid particulate contamination cumulatively for 5 ranges for contamination classes from 000 to 12. Fitch) provides a correlation of some different cleanliness specifications. The table (from An Encyclopedia of Fluid Contamination Control by E.C. The NAS system was originally developed in 1964 to define contamination classes for the contamination contained within aircraft components. NAS 1638 distributions) correlate reasonably with those obtained gravimetrically with AC test dust.

However, particle distributions which were determined to be representative of service distributions (e.g. Most commonly used cleanliness specifications are based on numbers of particles rather than gravimetric techniques. In this case contamination levels are described by the total number of particles per unit volume above a given size.įor example, the number of particles above 25 µ in size per 100 mL.

Additionally, contamination may be expressed as a cumulative concentration. These may be an interval concentration, for example the number of contaminant particles (per unit volume) between 5 and 15 µ in size.

Other techniques look at numbers of particles, describing contamination in terms of its size and concentration. For example, unless the size and density of the contaminating particles is known, no conclusions may be drawn relative to numbers of particles. The above techniques describe bulk or total contamination but give little information regarding size of contaminant.

0 kommentar(er)

0 kommentar(er)